COMPOSITE

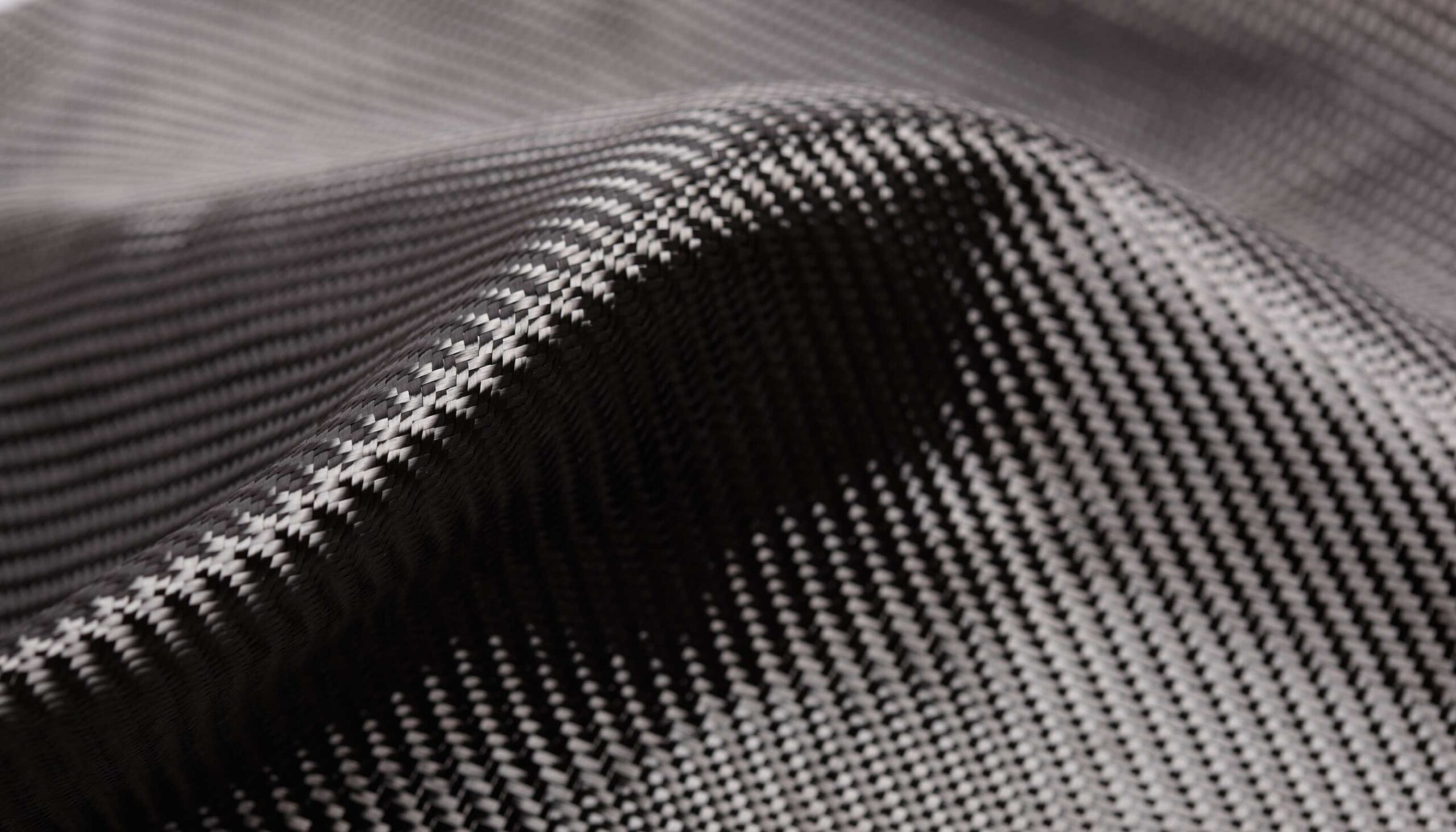

Why should you select composite instead of traditional materials? In many cases, composite combines a number of different properties which other materials lack. Many of our customers choose composite because it is light and strong. Others have discovered that it is only composite material which can handle the tough environment where the product will be used. A unique advantage is that the composite can be combined from different types of materials and tailored to precisely your requirements. For example, you can have a material that is flexible and adaptable or a composite that is thin, has torsional rigidity and a high level of strength.

When 1 + 1 becomes something

absolutely exceptional

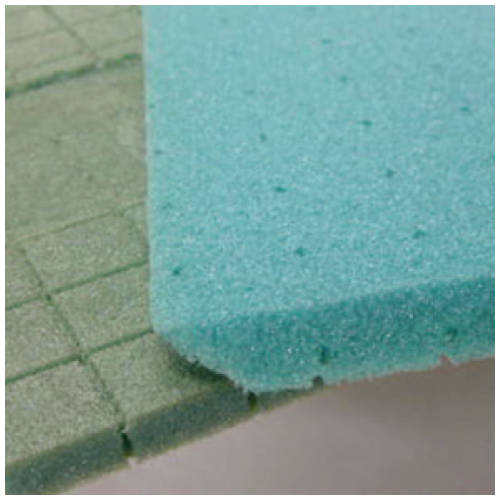

På Faiber har vi specialiserat oss på komposittillverkning och jobbar med alla möjliga sorters polymera At Faiber we have specialised in composite manufacturing and work with every conceivable kind of polymer fibre composites. A feature of these materials is that a fibre and a plastic join forces to create a material with a specific character. By combining a certain type of fibre with a selected plastic, we can manufacture composite materials with unique properties. In other words, customised solutions for precisely your requirements.

Fibre for every

conceivable application

We have a number of different kinds of fibre from which to choose.

- Glass fibre – cut into sheets or in the form of various kinds of woven fabrics. Glass fibre can also be supplied knitted into multi-axial products with two, three or four directions.

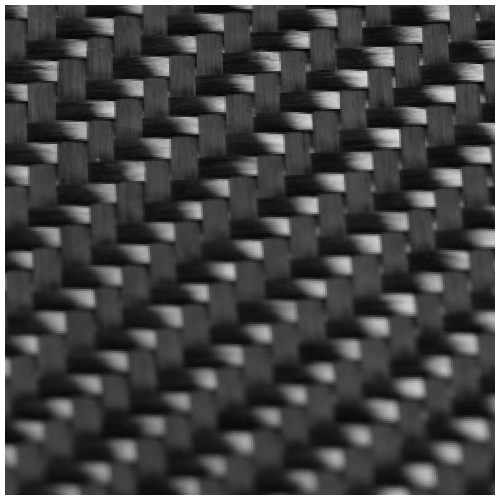

- Carbon fibre – aramid fibre and natural fibre. These materials can be supplied in a number of different designs depending on application.

MATRIX

(PLASTIC)

Combining the fibres with a certain type of matrix material depends entirely on the requirements placed on the finished composite. We assist you to find the optimum combination. We use polyester, polyvinyl ester and epoxy in a range of variants. Each variant has its own specific properties.

COMPOSITE IN A THOUSAND DIFFERENT WAYS

Light & strong

For many of our customers, the composite component’s low weight is of the greatest importance. At the same time, the aim is to have the strongest conceivable material and for the final product to have a very high finish. We are real heavyweights within this area.